ONI Rhytemper®

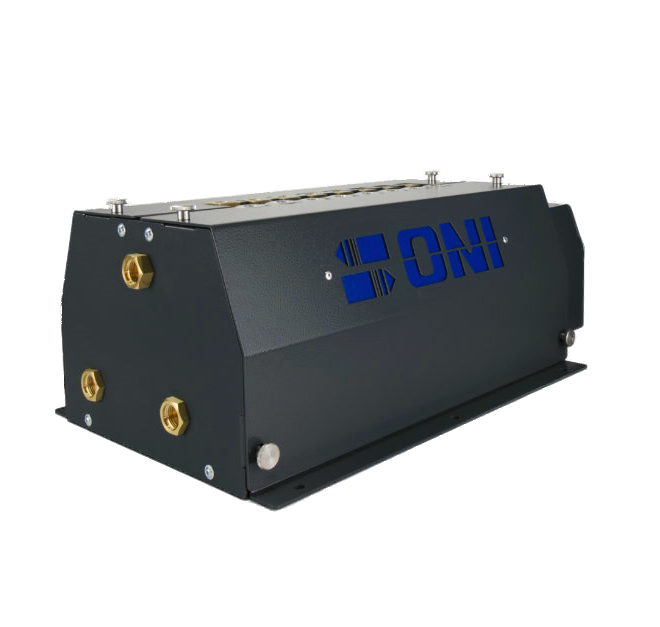

CorePulse

high-pressure cooling unit

Special features

- Powerful high-pressure piston pump (up to 25 bar)

- Efficient cooling through a large plate heat exchanger (indirect cooling 65kW)

- Monitoring and control of each individual quill

- Manual rinsing function for selected quills

- Automatic water exchange

Integrated monitoring unit and displays

- Central core break control (analysis per individual circuit)

- Digital monitoring of tank level

- Digital monitoring of the tank temperature

- Digital filter monitoring

- Digital monitoring of system pressure

- Recording hours of operation

Performance data | |||

|---|---|---|---|

max. water temperature |

70°C | ||

Pump System pressure max. volume Power |

20,0 – 25,0 bar 3,6 m³/h (60l/min) 4 kW | ||

Pressured air | 6 – 10 bar | ||

Cooling capacity | 65 kW | ||

Cooling circuit | |||

max. Number of single circuits (cores) |

32 | ||

max. Number of Dis | 4 | ||

Connection single circuits (cores) at distributor |

¼ inch | ||

Connection consumer (distributor) at the device forerun return |

¾ inch 1 inch | ||

Connection compressed air |

¼ inch | ||

Dimensions | |||

Length (with connection fittings) Width Height | 1070 mm (1200 mm)

490 mm 1000 mm | ||

Empty weight | 200-250 kg | ||

Tank volume | 70 liters | ||

Media supply | |||

Filling Pressure (min.) Connection |

1 bar 1 inch | ||

Cooling Pressure difference (min.) Connection |

0 bar

½ inch | ||

Operating voltage | 400 V AC | 3~ PE | 50 Hz |

ideally suited for deployment with quill cores or super short-term cooling cross-sections

The RHY-CorePulse series devices were specially developed for the multi-circuit cooling of quills and cores and are characterized by the control and monitoring of each individual quill with the temperatures and flow rates of each connected temperature control circuit and the individual circuits being checked and regulated.

A piston pump is used to effectively supply up to four 8-way manifolds with a high flow rate and higher feed pressure.

The pressure-monitored filters in the feed line and in the process return line and the air filter on the tank effectively protect against dirt and deposits produced in the process. The flushing function of selected quills and the automatic water exchange function effectively enhance its serviceability.

On standard models, the CorePulse supply unit is fitted with a PLC controller with a 7-inch touchscreen display, level and temperature monitoring unit, and a digital interface (RS485) used for communication of the cooling unit with the Rhytemper® FlexControl, FlowWatch or HotPulse control, and for remote adjustment.

Standard configuration

- - User-friendly PLC controller with a 7-inch touchscreen display

- - Digital interface RS485

- - Robust, powder-coated housing for industrial use

- - In RAL 7016 / 5002; special colors on request

- - Standard design on equipment castors

- - Corrosion-resistant stainless steel / brass materials

- - Filter on the equipment inlet and also in the consumer return included

- - 5-meter connecting lead with CEE plug

- - Fanless electrical cabinet with IP54 protection class

Optional equipment

- - Automatic water treatment through pH sensor and metering pump

- - Compressed air treatment unit

- - Analog or digital interfaces

- - 4 – 20 mA

- - Profinet

- - Profibus

- - OPC UA with Euromap 82.1

- - TTY

- - Special housing color

- - Special voltage