ONI Rhytemper®

FlowWatch Basic

Flowrate and temperature monitoring for self-installation

- maintenance-free water distributor for selfe installation

- can be installes in any mounting position

- highest measurment accuracy thanks to the vortex measuring principle without rotating parts

- short hoses

delivery contents

- robust system produced from brass

- can be supplied as a 4, 6, 8, 10 or 12 branch manifold

- distributor blocks housed-in (steel enclosure, anthracite colour coated)

- connection per plug & play

- flowrate measurement, measurement range: 1 – 15 l/min or 1.8 – 32 l/min

- max. media temperature: 125 °C (257°F) (10 l/min, 10 bar)

- basic visualisation unit included

- flowrate and return temperature monitoring of each individual circuit by means of tolerance value specification

- alarm function for deviations from flowrate or temperature values

measuring priciple | vortex | ultrasonic | |

|---|---|---|---|

measuring range flow | 1.8 – 32 l/min or | 0.3 – 75 l/min | |

| max. medium temperature | 125 °C (257 °F) | 100 °C | |

| Measurement medium | water | water | |

| Main media flow connection | 4 branch manifold: ¾ inch inner thread 6 branch manifold: 1 inch inner thread 8, 10, 12 branch manifold: | 4 branch manifold: ¾ inch inner thread 6 branch manifold: 1 inch inner thread 8, 10, 12 branch manifold: | |

Consumer circuit connection | ½ inch inner thread | ½ inch inner thread | |

| Nominal pressure | PN 10 | PN 10 |

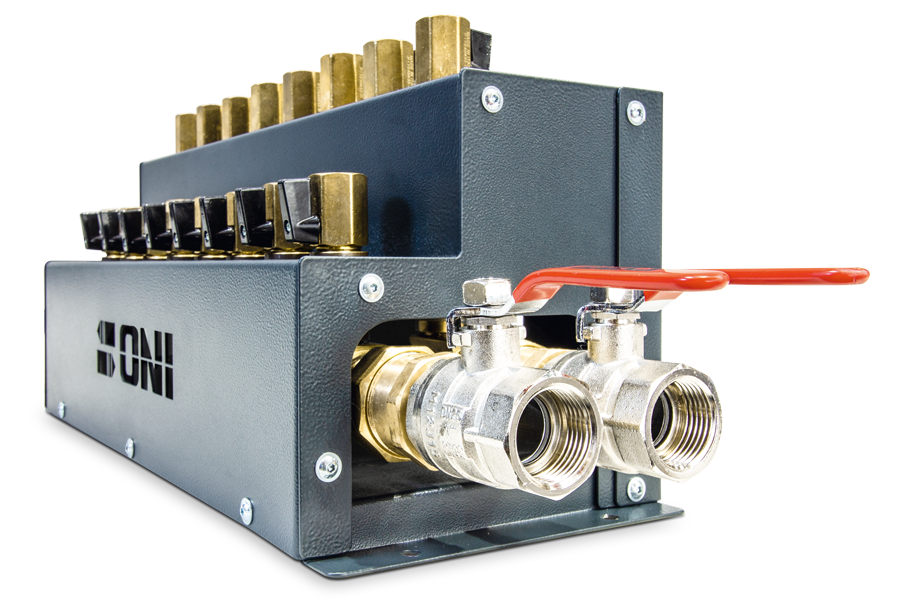

The RHYTEMPER® FlowWatch Basic is a completely electronic water battery for digital flowrate and temperature measurement in injection moulding. The low maintenance system is particularly impressive in its robustness of design, the clad distributor block, its high level of measurement accuracy and the simple, individual onsite self-installation.

The RHYTEMPER® FlowWatch Basic has been conceived on the modular design principle and can be supplied in the 4, 6, 8, 10 and 12 branch manifold expansion stages.

The core of the system is the design registered brass distributor unit composed of individual brass modules screwed together.

The anthracite grey enclosure provides high level protection for the compact RHYTEMPER® FlowWatch Basic distributor against mechanical stresses. This is produced as standard in coated steel and is conceived specially for each size of distributor block.

Labelling of the tooling hoses as well as the central water connection is integrated into the protective enclosure, clearly visible and permanently indelible.

Installation of the FlowWatch Basic distributor close to the tooling on the injection moulding machine is possible in next to no time. In so doing, only four threaded holes have to be made in the clamping plate to which the FlowWatch Basic is fastened.

The protective enclosure can be completely removed at any time or partially to change the vortex sensors.