ONI Rhytemper®

FlowWatch Professional

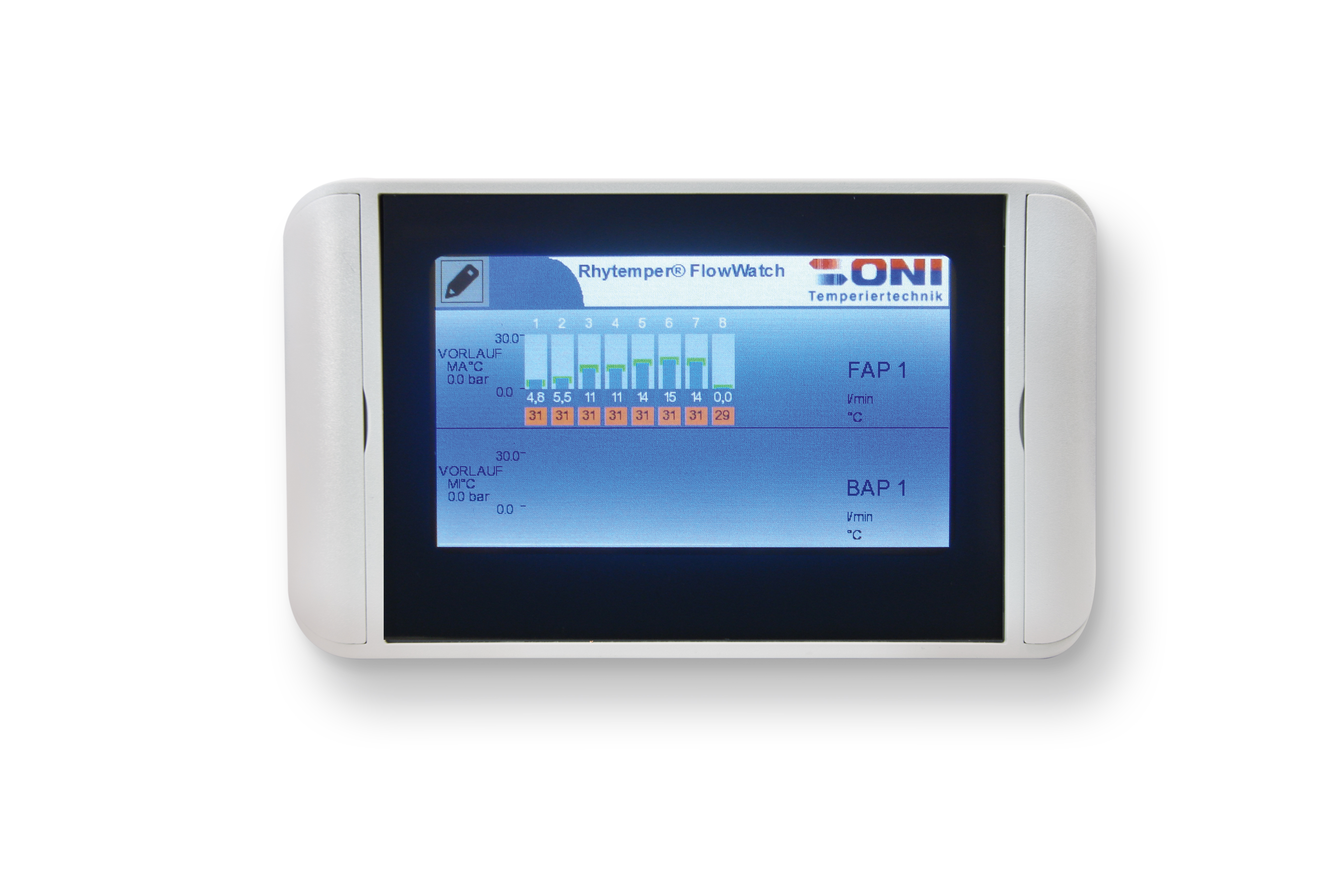

digital flowrate and temperature monitoring for injection molding

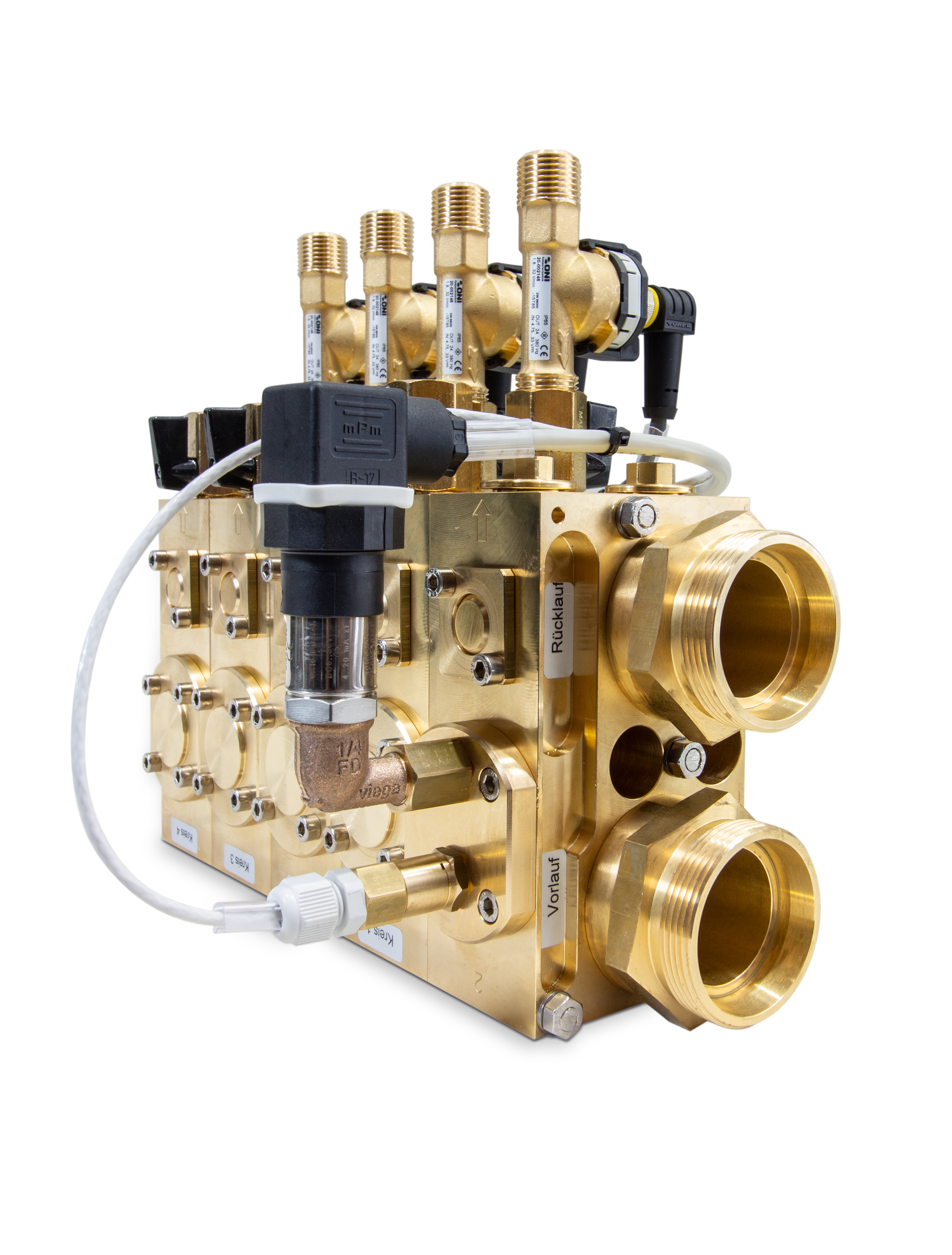

- Compact system of brass blocks

- Includes visualisation unit, optionally Mini with 4.3 inch, Midi with 5.7 inch or Profi with 10.4 inch touchscreen control panel, graphic process data display and tooling data storage

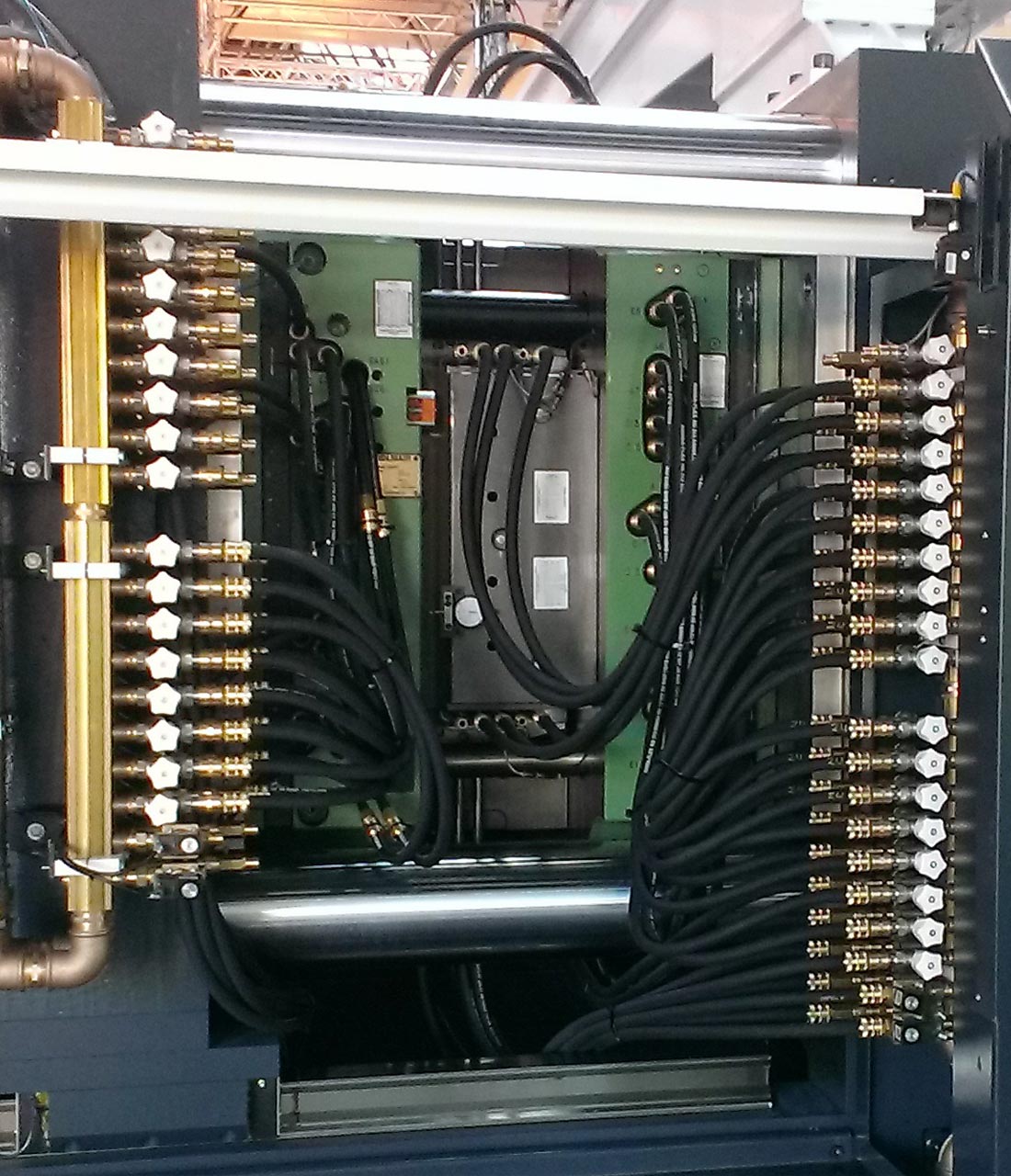

- Installation close to tooling

- Space saving machine integration

- Individual circuit lettering

- Flowrate measurement by means of turbine, vortex or ultrasonic measuring system in the feed line

- Flowrate calibration of all tooling circuits

- Includes flowrate regulation of each individual circuit by means of hand valve

- Expandable to the FlowControl, FlexControl and HotPulse multiple circuit temperature control systems

circuit control | handvalve | handvalve | handvalve |

|---|---|---|---|

measuring principle | turbine | vortex | ultrasonic |

measunring range flow | 0.3 – 40 l/min | 1.8 – 32 l/min 1.0 - 15 l/min | 0.3 – 75 l/min |

max. medium temperature | 85°C (185°F) 125°C (257°F) 160°C (320°F) | 125°C (257°F) | 100°C (212°F) |

measuring medium | water | water | water |

connection of main medium flow | 1½ inch IT | 1½ inch IT | 1½ inch IT |

connection of consumer circuit | ½ inch IT | ½ inch IT | ½ inch IT |

Nominal pressure | PN 10 / PN 16 | PN 10 | PN 10 / PN 16 |

The compact RHYTEMPER® FlowWatch Standard and RHYTEMPER® FlowWatch Professional water distributors are expandable at any time to the FlowControl, FlexControl or HotPulse multiple circuit temperature control systems.

The FlowControl system has a variety of setting options for individual utilisation of the impulse cooling operation, the continuous return flow temperature regulation as well as the flowrate regulation for each individual circuit. It consists of brass and, due to the building block structure of the single block modules, can be individually adapted to each plant with any number of measurement and regulation circuits. The greatest possible flowrates of up to 75 l/min of water are realised via a 1½ inch main water connection per distributor block module.

The FlowControl system enables the precise and fastest possible specification and regulation of a prescribed flowrate value per individual circuit by means of electric proportional valves. These are located, as is the integrated volume flow measurement, in each consumer feed line, whereas the temperature measurement takes place in each consumer return line. The measurement sensors are hard wired in an electronic box which communicates with the visualisation unit via a bus system.

The simple and clear operator interface enables rapid and optimum setting of the system on the production process. Each individual circuit has individual flowrate calibration as well as flowrate identification. Besides specific freely selectable modes of operation (continuous cooling, continuous temperature control and impulse temperature control), the visualisation unit provides a graphic display for the cooling water flowrate, a flowrate diagnostic function and multilingual user guidance which permits the creation of password protected user levels. If required, preheating stations/temperature control units can also be activated from the visualisation unit. All set parameters can be assigned to a tooling set and saved as a dataset and subsequently retrieved. Data backup can also be effected externally via the front-located USB interface. Data transfer to MES systems can take place via the integrated Ethernet connection which also provides the prerequisite for remote maintenance.

Numerous other special functions and configuration options form the basis for our experienced application technicians to make the optimum adjustments for economic temperature control with the respective production processes.